Vibrating screen

1.Uses and characteristics of machines:

This equipment is a rotary vibrating screen. Short for “vibrating screen “. (1) Y series of motors or explosion-proof motors are used to drive the vibrator through flexible transmission. (2) Vertical vibration motor. The vibration force can be changed by arbitrarily adjusting the two groups of heavy hammers and phase angles on the vibrator, so that the material on the sieve surface can move in complex shape, and the motion track of the material on the screen surface can be adjusted.

2. Principles

The rotary vibrating screen is composed of three parts: feed hopper screen, core vibration and body seat. The inside of the body seat is the transmission and vibration part, and the shock absorber assembly is fixed through three sets up and down. The adjustable eccentric weight hammer rotates with the drive motor to produce centrifugal force and is controlled by shock absorber to achieve the desired performance.

3. Specification

|

TYPE |

Capacity(kg/h) |

Mesh |

Motor power(kw) |

Speed (r/min) |

Export height (up*middle*below) |

Dimension |

||

|

XZS-515 |

≥320 |

12-1000 |

0.18 |

1400 |

1080 |

950 |

760 |

880×780×900 |

|

XZS-650 |

≥500 |

12-1000 |

0.25 |

1400 |

1140 |

960 |

820 |

880×880×900 |

|

XZS-800 |

≥800 |

12-1000 |

0.75 |

1400 |

1160 |

990 |

830 |

1050×1050×1000 |

|

XZS-1000 |

≥1100 |

12-1000 |

1.1 |

960 |

1200 |

1050 |

850 |

1400×1250×1500 |

|

XZS-1200 |

≥1400 |

12-1000 |

1.1 |

960 |

1200 |

1030 |

830 |

1650×1460×1600 |

|

XZS-1500 |

≥1900 |

12-1000 |

1.5 |

960 |

1180 |

1000 |

800 |

1950×1650×1660 |

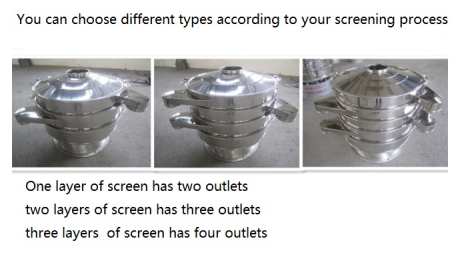

4.Photos for reference